|

Technical Audio Group |

|

|---|

tag|zero: driving towards zero carbon

Powered by sunshine, TAG dials up its local delivery options.

Technical Audio Group is now making carbon neutral deliveries around Sydney with an all-electric/solar charged eight ton/eight pallet truck.

Having long wanted to improve the certainty of local deliveries, particularly those direct to work sites where access is limited and where timing needs to be flexible and reliable, Team TAG researched the options and settled on a beauty, with the SEA 300 EV.

"As a service to our customers we want to guarantee deliveries and we were finding that local couriers just don't have the flexibility to wait and make sure difficult deliveries are completed." Said TAG Warehouse manager Shane Linfoot. “You can’t blame them they’re on a tight schedule and have to complete their runs, but it doesn’t work when one of our deliveries is critical and that’s why we made the decision to take control of those sort of deliveries ourselves."

But why go electric? An electric vehicle is consistent with TAG’s commitment to sustainable solutions, and the SEA 300 EV is designed and built in Australia so ticks a lot of boxes.

"On paper an eight-ton electric truck is an eye watering investment that doesn’t make financial sense." Stated TAG CFO Craig Durrant. "If it was purely a business decision, we wouldn’t have taken the leap but there are much bigger factors at play here, like the environment and the condition of the planet we pass onto the next generation. Every time tag|zero hits the road it serves as a powerful reminder that a carbon neutral solution is not only possible but in fact a serious and viable option. And the lack of exhaust emissions is something everyone out in traffic can enjoy immediately!”

With the unprecedented demand for all things EV it took 18 months for TAG’s shiny new SEA 300 EV to be delivered. SEA-Electric are an Australian company and a global leader in electric commercial vehicles. The SEA 300 EV utilises a Hino cab/chassis with the diesel engine and gearbox replaced by a SEA-Drive electric power system plus batteries sufficient for a 220km range. The company manufactures around five electric trucks every week at its Dandenong, Victoria facility.

With 108Kw solar array on their Kings Park warehouse roof tag|zero is charged directly from the sun.

"There’s something beautiful and compelling about turning sunlight into local deliveries.” said Shane. “We're working our solar array pretty hard now with nine electric warehouse vehicles, the odd EV charging up and now tag|zero. Nonetheless if you’re passing by, you’re still very welcome to drop in for some free juice, and if you see tag|zero on the road please give us a wave.”

In early 2021 we purchased a warehouse at Kings Park/Sydney to serve as our logistics centre. With owning the property and controlling what goes on inside it comes a free hand to implement our sustainability vision.

Here’s a snapshot of what we’ve done so far – it’s a waypoint on a journey that never really ends.

There are five central elements:

POWER: Generation/Use/Future

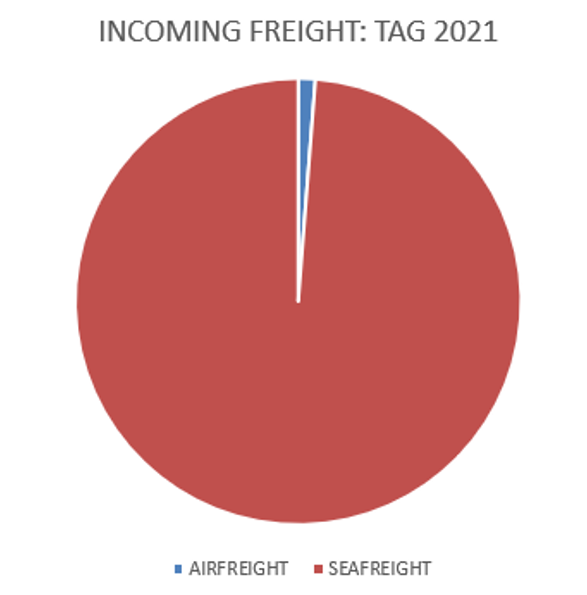

INCOMING FREIGHT: Airfreight vs Seafreight

WASTE STREAMS: Recycling/Reuse/Disposal

INPUTS: Reduction/Alternatives

ENVIRONMENT: Workplace & Planting/Greening

POWER

The long term vision is to be 100% solar powered, to store power and be removed from the grid.

Current Status:

Solar Power: 100Kw ABB System (300 x 325w solar panels) installed and generating.

Use: All machinery is electrically powered including warehouse vehicles (5 forklifts, 2 WAV pickers, a floor sweeper and a floor scrubber).

EV charge station installed for staff and guests electric vehicles.

EV delivery Truck (on order). September delivery.

INCOMING FREIGHT

AIRFREIGHT vs. SEAFREIGHT

In late 2019 TAG committed to use SEAFREIGHT (vs AIRFREIGHT) as a priority for environmental reasons!

Seafreight is unquestionably much more environmentally friendly than airfreight. For a typical shipment of one ton over 5,000km around 75kg of CO2e gas is emitted when transported by sea and around 3,300kg when transported by air. (CO2e being Carbon Dioxide equivalent in terms of impact from greenhouse gas emissions).

Seafreight is also cheaper per Kilo but often for small shipments (below 1m3) the much higher handling costs and port charges incurred on a seafreight shipment often means Airfreight ends up being cheaper.

Plus airfreight is heaps faster so for high value/low volume products the reduced funding time (having your money tied up for two months rather than, say, two weeks) can be significant. In addition when sales volumes are very varied from month to month and the product has various colours/finishes/sizes etc., carrying zero stock and airfreighting everything to order can be very attractive to a distributor.

In late 2019, and incorporating all those arguments, TAG was around 90% Seafreight vs 10% Airfreight. To maintain the same product availability TAG made a series of tough decisions around product range rationalisations, increased local inventory, bulked up shipment sizes, and, to maintain a full pipeline of stock in transit, started ordering 4-8 months ahead.

COVID era has severely challenged the plan and supply chains generally but TAG has been staying as true as possible to the seafreight strategy and only using airfreight for very small or critical supplies. For the last 12 months we’re at 98.75% SEAFREIGHT with plenty of inventory on hand and ironing out some kinks so we can do even better.

AIRFREIGHT: 11,138KG

AIRFREIGHT: 11,138KG

SEAFREIGHT FCL: 844,800KG

SEAFREIGHT LCL: 47,344KG

WASTE STREAMS

In amongst the approx. 900 tons of products entering our warehouse in 2021 there were a variety of by-product waste streams. Often this ‘waste’ just gets consolidated into ‘comingled’ bins that end up on a sad downward spiral to landfill. We wanted to minimise that so we set about identifying the waste streams and looking for reuse/recycling opportunities for each.

We are now accurately separating waste into:

- Cardboard/Paper.

- Soft plastics/pallet wrap.

- Pallets: Timber, Plastic, Cardboard, Metal.

- Pallet strapping etc.

CARDBOARD/PAPER:

Comprises largely cardboard cartons.

1. Where possible we reuse cardboard cartons as cardboard cartons for outgoing despatches. (‘Reuse’ is near the very top of the waste hierarchy!)

Our requirement for new cartons is thereby reduced as is the overall quantity we then need to recycle/waste.

2. For internal box packaging where bubble wrap is commonly used we now employ a Rongda cardboard box recycler. This machine produces an excellent packaging material for cushioned protection or just void filling and is powered by our solar array.

3. The balance of broken cartons, paper, waste cardboard etc heads to the Bramidan baler where it is compressed and baled for our waste partner Wanless to pick up and sort for recycling and reforming into the next generation of paper/carboard products.

SOFT PLASTICS:

Pallet wrap is quite frankly a magical product! It is light, strong, cheap, secures product on pallets and is universally used on EVERY pallet on EVERY shipment. If you’re in the logistics business it’s just really, really hard to be without it and you’re going to be dealing with a lot of it because it is definitely only single use.

Co-mingled in waste bins it’s basically off to be landfill but it can be recycled and because it is a feed-stock for other products it has value! But it’s value can only be released if the product can be transported efficiently. This is a “cost of truck movement vs value of goods being moved” argument and in the case of pallet wrap it’s dead unless it’s compressed and bailed.

Our Bramidan compresses pallet wrap to around 5% of it’s former glory then neatly bales it. When we’ve got 5 or 6 bales Wanless picks it up and actually pays us a small amount for it! We’re not in it for the money but when money changes hands it means it has value and no one pays money for something and then throws it away!

Wanless are an aggregator and in this case when they’ve accumulated a couple of hundred bales they’re able to sell it to traders who on-sell it to manufacturers of things like builders wrap, car bumpers, park furniture, wheelie bins etc.

PALLETS:

As previously said: ‘Reuse’ is near the top of the waste hierarchy!

Some pallets companies, like CHEP and LOSCAM, have made a business out of exactly that but their pallets are the hardwood reusable type. The pallets we are dealing with are the single trip, disposal, cheap and cheerful type.

How do we deal with them?

1. Where possible, and if the pallets are in good condition and structurally strong, we re-use them for our own outbound despatches.

2. We offer our pallets FOC to companies in our neighbourhood who use them for their own outbound despatches. They take most of the balance.

3. Where pallets are in poor condition, are broken or unusable they are picked up by Wanless who aggregate and recycle where possible.

Hard to be exact but around 90% of our pallets are reused as pallets (1 and 2 above). 10% are consigned to Wanless.

PALLET STRAPPING ETC:

Sadly for several waste streams, and pallet strapping is one of them, no local recycle channels exist so landfill is the only option. At some point, hopefully soon, recycling channels will become available but until then we are reducing our landfill waste to it’s smallest possible volume.

That’s where our industrial granulator comes in. This beast makes short work of things like pallet strapping and pallet corners from the warehouse and hard plastics, rubber, silicone, unrepairable headphones, turntables etc. so it’s also a part of our E-waste programme.

By granulating these waste streams we’re able to reduce volume by about 90% and, as well as less waste volume that also means 90% less truck movements!

As said this is still waste going to landfill but until recycling streams become commercially available it’s the least worst solution! Hopefully over time we can make the granulator redundant.

INPUTS

PALLET WRAP:

As previously mentioned pallet wrap is a silver bullet for warehousing. With inbound pallet wrap we’re baling and recycling but we also using pallet wrap for our outbound pallets.

Our aim is minimisation and searching for viable alternatives. At this stage we’ve invested in two Lantech Q-300’s automatic wrapping machines which as well as being super safe offer two great environmental advantages.

1. The wrap can be recycled and is one of the thinnest at just 25micron.

2. It stretches up to 300% So a 100m roll of pallet wrap can be stretched up to 300m and that’s a lot less wrap used.

3. The amount of wrap used on each pallet is standardised and minimised.

PAPER TAPE:

We can’t promise that we’ve eliminated plastic packing tape at TAG but we’re having a go!

Obviously using paper sealing tape on cardboard cartons (not plastic tape) makes perfect sense when those cartons get to the recycling stage.

It also means less plastic and that’s a goal in itself!

The Better Packages machine spits out strips of paper tape – cut to length – and it seals quickly, easily and very neatly!

It’s a dream and when you use it you feel a strange sense of calmness and peace.

That peace quickly dissolves when you carry it from carton to carton on the fly! That’s where a plastic tape gun is hard to beat.

We bought the first machine to seal up three hundred ONWARD&UPWARD Come Back Packs and it’s now on permanent sealing duties at our Stanmore service centre.

We’ve just purchased machine #2 initially for production runs (like Audio-Technica Content Creator Packs) at our Kings Park logistics centre.

We’re secretly hoping to buy more – Warehouse Team allowing!

ENVIRONMENT

WORKPLACE:

It may be a workplace but that doesn’t mean it’s has to be dull. With Sindy Sinn's help it’s not dull! Kinda scary TBH!!

PLANTING/GREENING:

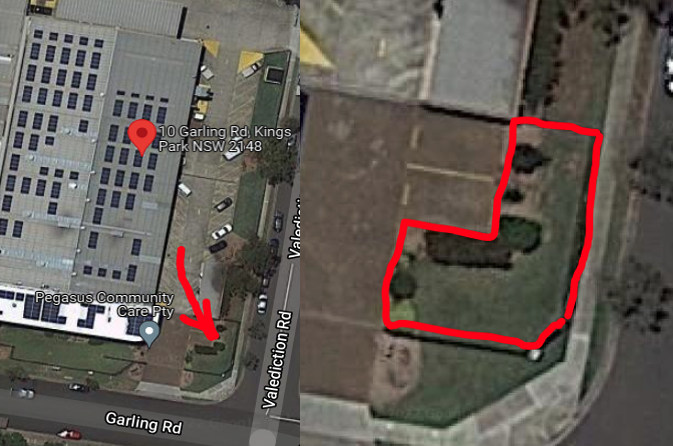

A suitable parcel of land existed at the TAG Kings Park site for a Miyawaki Forest.

This technique, pioneered by Japanese botanist Akira Miyawaki, creates a dense, native forest in a small space, which sustains itself and supports local bio-diversity. Three or four plants are placed in each square meter, so the trees grow UP quickly, rather than OUT slowly!

The Miyawaki Technique is proven worldwide. More than 3,000 forests have been successfully created. It is much more dense that conventional plantations and provides up to 30 times better Carbon-dioxide absorption as compared to a monoculture plantation.

It is a completely maintenance-free, wild and native forest after three years.

At the South East corner of the 10 Garling Road site is a land parcel approximately 175m2. It offers plenty of direct sunlight and is well drained. It was considered ideal for the planting of a Miyawaki Forest.

TAG'S MIYAWAKI FOREST AND MEDITERRANEAN CITRUS GROVE:

13th November 2021 was planting day for Team TAG - a total of 315 trees!

A Miyawaki Forest with 300 native plants: canopy trees, medium height trees, shrubs and ground cover plus 15 in a Citrus Grove with oranges, lemons, limes, olives and pomegranates.

The concept of the Miyawaki is to create a dense forest in a small space the Citrus grove is all about fresh fruit for us and you (whenever you visit). Mmmmm.

All the plants in the Miyawaki trees are natives and indigenous to western Sydney. We sourced them from IndigiGrow an Aboriginal owed and staffed nursery in La Peruse www.indigigrow.com.au. They were easily able to provide us with the 25 odd species we needed and we’d def recommend them!

We planted them all and they’re growing as we speak!

Hugely successful day and many thanks to all involved. Both projects completed on time, many obstacles overcome (with ingenuity and teamwork), a fine BBQ lunch consumed and only three casualties (two mattocks and an axe)!

Great TAG team project and awesome to do one little thing for our beautiful planet!

Technical Audio Group is a contributing member of the Australian Packaging Covenant Organisation (APCO). APCO is a not for profit organisation partnering with government and industry to reduce the environmental impact of packaging in Australian communities. APCO delivers this model of shared responsibility through the promotion of sustainable packaging activities including sustainable design, recycling initiatives, waste to landfill reduction and circular economy projects.

TAG aims to minimise its environmental footprint - do more good than harm. TAG is committed to:

- Using as few resources as possible across our operations

- Using renewable or recyclable inputs for our operations

- Influencing our suppliers – of products, business inputs and services – toward shared goals

- Influencing our customers and our communities toward shared goals

Our FY2021 Packaging Goals Include:

- 25% of product packaging to have some renewable or recycled content

- 100% of distribution packaging to be recyclable

- 100% of distribution packaging to display Recycling Lapel

- Recycle 70% of solid waste

For more info on APCO please visit https://www.packagingcovenant.org.au/

Policy on Slavery and Human Trafficking

We support, and respect internationally-declared human rights protections, and strive to fulfill its social responsibilities. Therefore, we never tolerate any forms of modern slavery such as servitude, forced and compulsory labor, bonded and child labor, sexual exploitation, human trafficking and related forms of workplace abuse.

As a globally recognized brand we are committed to ethical working practices and responsible business practices worldwide. We are continuously working to improve our practices and to acting ethically and with integrity in all our business dealings and relationships. In addition, we expect and require the same from our suppliers, contractors and other business partners.

For more info on Audio-Technica's Policy on Slavery and Human Trafficking please download the following PDF:

Audio-Technica's Policy on Slavery and Human Trafficking (PDF)

Green Procurement of Products

Under our “management philosophy on the environment,” we intend to promote the manufacture of eco-friendly products together with our suppliers. To that end, we created and issued the first edition of Product Environmental Quality Standards for the audio-technica Group to determine substances whose use and/or inclusion is prohibited or controlled according to the trends in society and laws in June 2006 and have since been promoting green procurement.

We request our suppliers to understand our eco-friendly efforts, promote the establishment, maintenance, and improvement of their environmental management system, and reduce the environmental impacts of their purchased parts and materials according to the Product Environmental Quality Standards for the audio-technica Group.

For substances or their uses which are not clarified in these Environmental Quality Standards but whose use is prohibited or restricted by state or regional environmental laws or regulations, we will comply with those laws or regulations.

For more info on Audio-Technica's Environmental Quality Standards for products please visit the following:

Audio-Technica Environmental Quality Standards for Products (PDF)

Audio-Technica Environmental Conservation Activities

Our Corporate and Social Responsibility

Allen & Heath and parent company Audiotonix are progressive innovators. We are the largest provider of audio mixing consoles and accessories in the world today. Our highly talented workforce care about the materials and technologies we use in our designs, and how that affects our customers, our combined environmental footprint and our communities.

For more info please visit https://www.audiotonix.com/responsibility/

Green Statement

As responsible members of the business community, it is our desire and pledge to leave the environment better than we found it. As consumers of the earth's resources, we consider it our responsibility to reduce and if possible eventually eliminate the environmental impact of our manufacturing processes.

As a matter of policy, QSC complies with all applicable environmental regulations. This includes (but is not limited to) global environmental laws, such as EU RoHS Directive (2011/65/EU), EU WEEE Directive (2012/19/EU), China RoHS, Korean RoHS, U.S. Federal and State Environmental Laws and various resource recycling promotion laws around the world.

At QSC we follow the Three R's:

1. REDUCE

The best thing that we can do for the planet is to use less of it. Reduce refers to lessening the amount of items or resources that are consumed, using only the amount that is needed, and looking for alternatives that will lessen our use. This includes purchasing durable, long-lasting goods; products and packaging that are as free of toxins as possible; and redesigning products to use fewer raw materials. QSC uses several different types of source reduction packaging and janitorial supplies. One of our primary goals is to design products that conserve resources and energy while producing more efficient, thinner, and lighter products - without compromising the performance.

2. REUSE

When making purchasing decisions, we consider items that are durable and reusable. Extending the life of a product or repurposing an item rather than discarding it is an effective means of reuse. This is considered to be even better than recycling because the item does not need to be reprocessed before it can be used again. By reusing products you can keep operational costs down and do your part to be environmentally friendly. QSC Reuses products such as loosefill material, for cushioning; it requires no maintenance, and reduces inventory space. QSC also has reusable containers that are returned to suppliers for the next delivery.

3. RECYCLE

Recycling turns materials that would otherwise become waste into valuable resources that can be used to make new products. In addition, it generates a host of environmental, financial, and social benefits. It is significantly better than throwing materials away which then get sent to landfills. Recycling also includes buying products with recycled content. In order to make recycling feasible, we must buy recycled products and packaging. By doing so, we create a benefit, both economical and environmental. Purchasing products made from, or packaged in recycled materials saves resources for future generations. As we all know all good things come to an end but before you dump your packaging into a landfill try recycling. For the many materials that cannot be eliminated through source reduction or be as effective this is where recycling comes in. QSC products replaced with newer systems can be retired to other venues or become rental systems. By recycling our package, materials and supplies we minimize the amount of waste generation by recovering and reprocessing usable products.

For more info on QSC's Environmental Policy please visit https://www.qsc.com/about-us/green-statement/