|

Technical Audio Group |

|

|---|

Product Stewardship

At TAG we’re committed to being responsible for the products we sell. We’re making continual improvements in our sustainability initiatives and we’re working with the manufacturers we represent to help us reduce environmental impact.

At this early stage of our journey, we’re focusing on e-waste as it is the fastest growing waste stream in the world. Annually over 50 million metric tonnes of e-waste is generated globally. Such a massive and difficult challenge requires all players to respond, and as distributors of electronic goods, it’s something TAG must responsibly address.

We’ve assigned this dedicated web page to Product Stewardship to signify how important we think it is and to share what we are doing. Although there’s not much content right now, that's not because we haven’t been thinking about, working on and trialling ideas.

We’ll populate this page as we make progress and waypoints. The journey will be a long and evolving one and we’re learning as we go, so please reach out if you have ideas and solutions that can help.

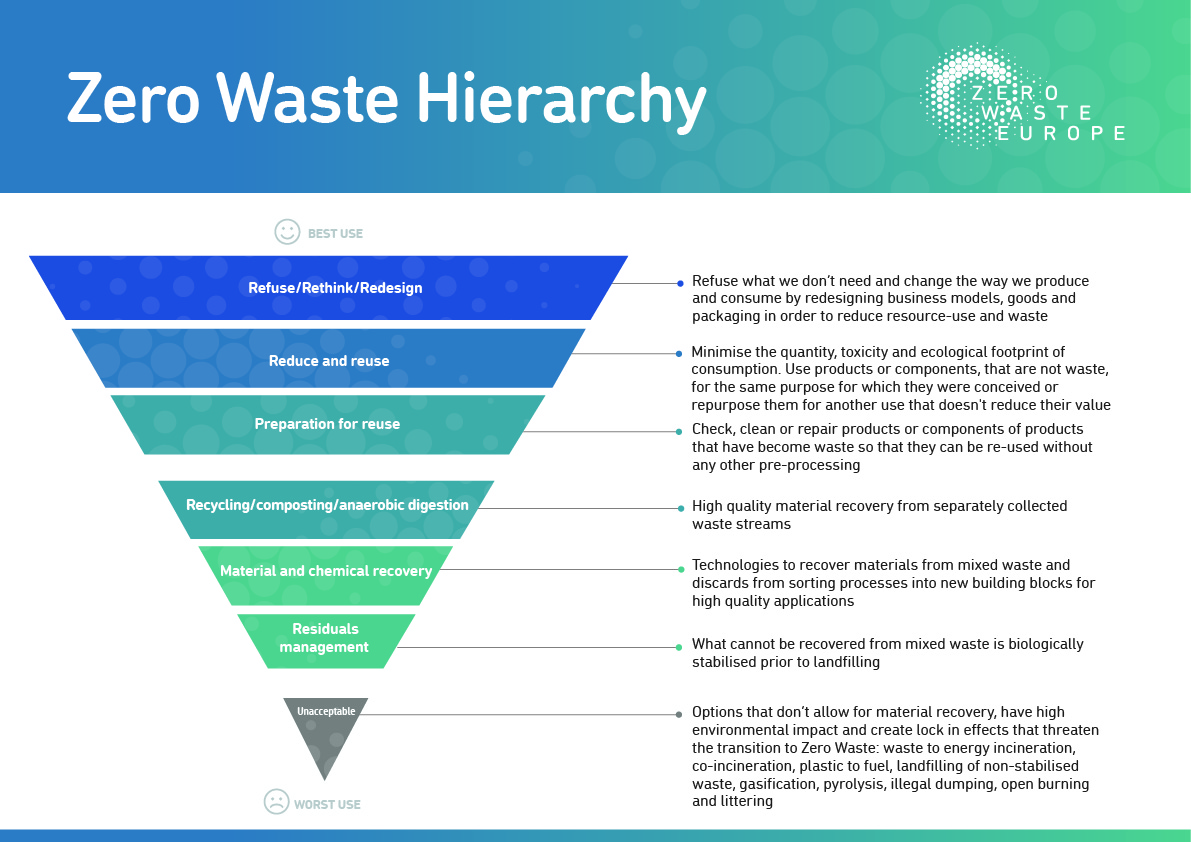

The North Star for our Product Stewardship initiative is the Zero Waste Hierarchy. Where possible we’re trying to find solutions at, or at least near, the top. If the product is no longer able to be repaired, it’s all about component separation and finding the best recycling path for each material.

Zero Waste Hierarchy, Zero Waste Europe

Source: https://zerowasteeurope.eu/

REUSE

Where possible we reuse by checking for NFF or quick repair status and allocating to promotional stock or reboxed.

High volume return example are:

Headphones: Used by A-T/TAG for promotional/sponsorship purposes.

Turntables: Offered at 50% discount to selected independent record stores (ie. Crosstalk Records, Scratches Records).

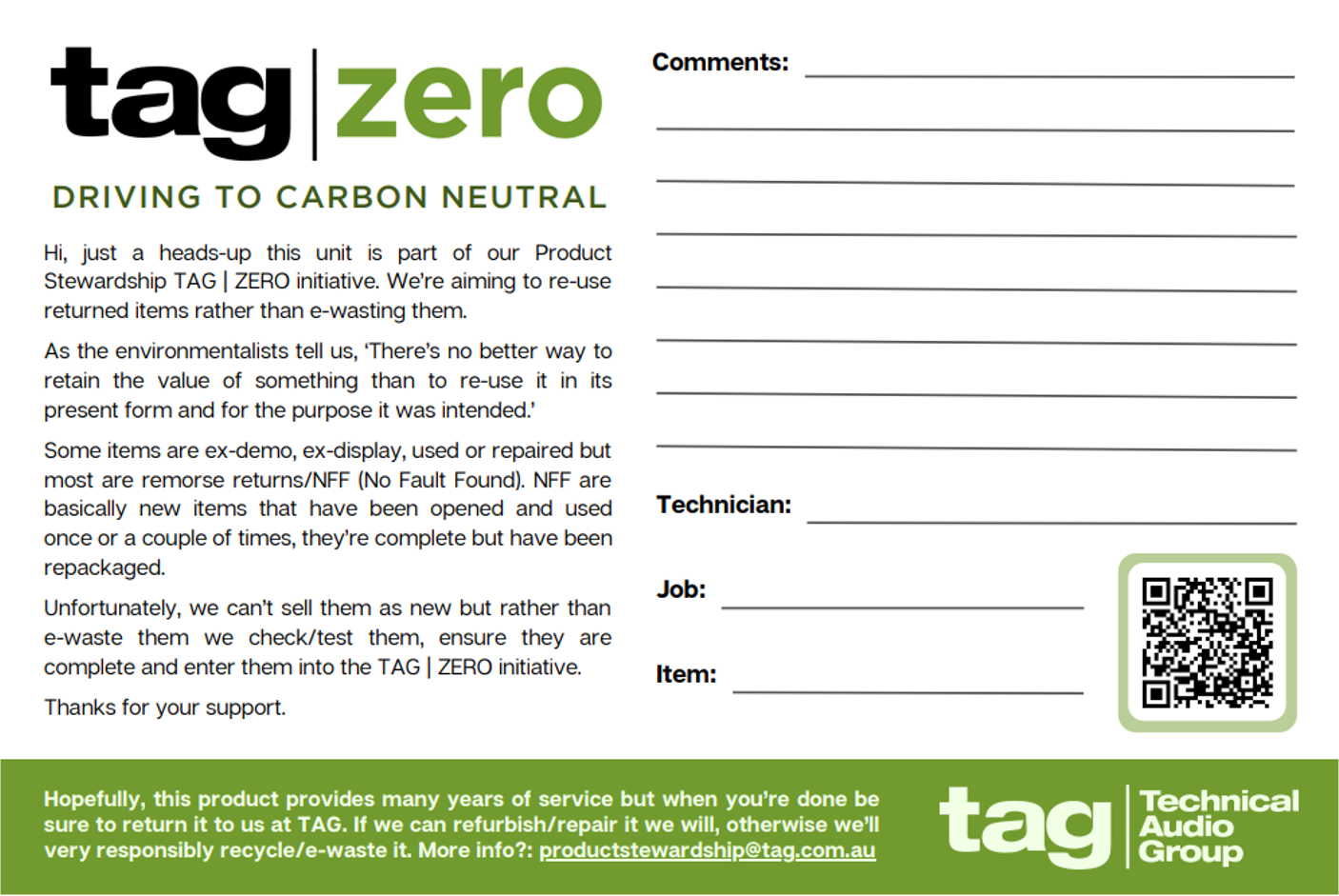

This sticker is placed on repaired items.

WASTE STREAMS

If it’s an EOL (End of Life) Allen & Heath, Audio-Technica, Martin Audio or QSC product, bring it to us at TAG and we’ll ensure that it is handled in the most environmentally responsible way we have access to.

That’s our commitment as a distributor – to take EOL responsibility for the products we sell. How we handle each product is evolving and it very much depends on the state of the device, and the materials contained within. One thing is clear, if something can be passed on to one of our trusted recyclers and repaired to give it a second-life, that’s a win. Our early moves have been to enlist Arnie’s Recon who have done an excellent job of handling these processes for us, but there is always room for further improvement, so watch this space!

If the product is no longer able to be repaired, it’s all about component separation and finding the best recycling path for each material.

For Example: Bluetooth headphones contain a vast array of materials. What we’ve learnt so far is that there are effectively five waste streams available to us.

Batteries: Over time TAG accumulates commercial quantities of batteries both from Bluetooth headphones and general use in wireless microphones etc. plus we encourage staff to bring in their dead batteries so we can dispose of them properly.

There’s only one onshore battery recycler in Australia, Envirostream Australia, and by all reports they’re pretty good at what they do which, basically, is to recover as much of the underlying material content as is technically possible. So, at this stage ‘in Envirostream we trust!’

Within the general category of batteries, we are separating into two types which we box accordingly:

Alkaline batteries: common single use types and typically used in portable electrical devices (AA, AAA, D, C etc). We prepare these by taping the terminals (to prevent inadvertent discharges and potential sparks/fires).

Lithium-ion (NMC & LCO chemistry) re-chargeable batteries: as typically used in BlueTooth headphones and In-Ears. These are a bit trickier and time consuming because they permanently reside in the device they are powering and are hard wired and secured. Separating them out generally involves unseating/dislodging them from their mounting (double-sided foam tape, adhesive glue or cable ties) and clipping their connecting wires/terminals.

PCB: Contains recoverable metals. We consolidated and recycle via Arnies Recon who in turn further consolidate and ship to USA for metals extraction and other materials recovery.

Cables: Stripped for copper recovery by our own in-house metals guru Jarod Hughes.

Paper/Packaging: General paper/cardboard is recycled via the council blue wheelie bins. For large quantities TAG processes via our Rongda cutter to produce an excellent packaging material for cushioning protection or just void filling.

Metals: TAG separate\s metals into Steel/Iron and Aluminum. Both go to Arnies and then Sydney Metal Traders (SMT).

Remainder: Plastics, metals, headband, fibre, hard plastics, rubber, silicone, unrepairable headphones, turntables etc. Stuff that is too hard to separate and even if separated there’s no viable recycle path. One way or another this waste stream is headed to landfill so we’re making it as compact as possible, firstly to minimise the volume of landfill and secondly to reduce the number of truck movements required to get it there. We add to this waste stream some waste Streams from our warehouse operation like pallet strapping (where likewise there is no viable recycle path) and granulate it. TAG‘s Granulator takes no prisoners and granulates mixed waste streams into a very compact and bagged result less than 10% of its original volume.

Short story. We’ll take EOL responsibility for the products we sell and we’ll also be environmentally responsible. That’s a lot of responsibility! But that’s our commitment.

Initially our EOL welcome mat is at 43-53 Bridge Road Stanmore NSW 2048. Contact us on productstewardship@tag.com.